The topic of recycling is increasingly becoming the focus of politics, business, and society. We want to focus on the positive and show that, despite all the problems, things are slowly but surely moving forward in several areas of the economy. We take a look at advanced recycling technologies for flexible packaging and explore their potential and limitations. We also provide examples of concrete developments in the complete recycling of HDPE packaging, a dairy cup with 30% polystyrene recyclate, and a strong alliance between two major players.

Structurally, the situation regarding plastics recycling remains worrying. The industry association Plastics Recyclers Europe (PRE) recently announced that Europe has lost almost one million tons of recycling capacity since 2023. “The Netherlands, Germany, and the United Kingdom are particularly affected. In the first seven months of 2025 alone, as much capacity was lost as in the whole of 2024 – and three times more than in 2023. For the current year, no growth is expected for the first time in years,” according to PRE.

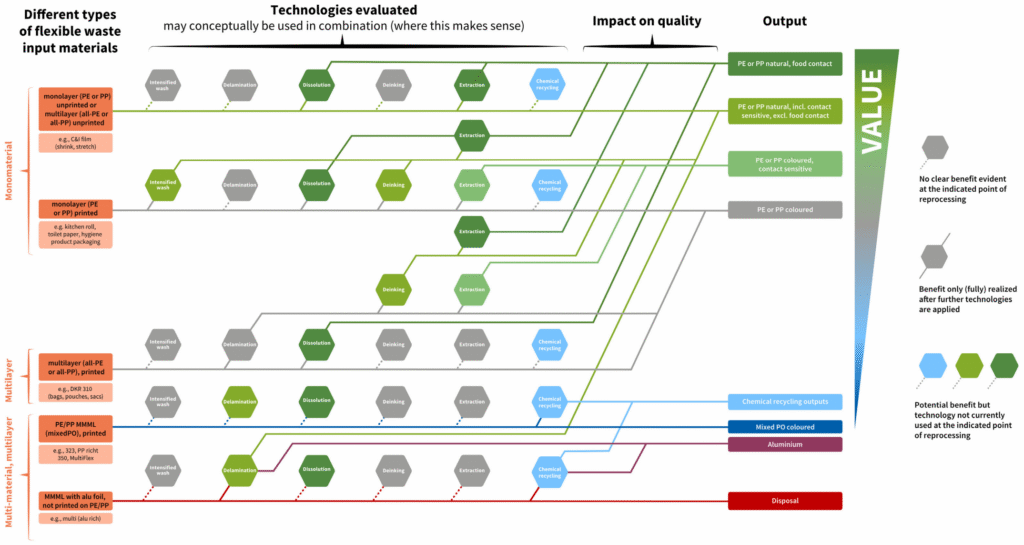

Advanced recycling technologies for flexible packaging

There is a lot of potential, but also many limitations. That’s how the issue can be summed up in a nutshell. But let’s take a closer look.

The CEFLEX (Circular Economy for Flexible Packaging) initiative, in collaboration with Ghent University, has evaluated various advanced recycling technologies. The focus was on five approaches:

- delamination,

- deinking,

- dissolution,

- contaminant removal, and

- advanced wet friction washing.

Results

The results show that many processes have been technically tested, and some are already in use. These include

- delamination, in which multi-layer packaging such as PE-aluminium is separated in a 32,000-ton plant in Germany, and

- the “Cadel Deinking®” process, which removes up to 95 percent of printing inks.

- Advanced Wet Friction Washing removes surface contaminants and delivers a recyclate yield of over 70 percent.

- Dissolution and contaminant extraction, such as with supercritical CO₂, enable virtually pure material – an important prerequisite for applications of the highest quality.

Challenge

Most technologies currently exist only on a pilot or niche scale. Large-scale plants are missing, material complexity makes processing difficult, and investment cycles fall behind political requirements.

This threatens to derail the goal of the EU Packaging and Packaging Waste Regulation (PPWR), which stipulates high recycling and recycled content targets by 2030.

CEFLEX’s conclusion

New processes are valuable accelerators, but they cannot replace the fundamentals, such as optimized packaging design. Only through the interaction of technology, market, legislation, and design improvement can high-quality recycled materials be obtained on a larger scale and the cycle be closed.

BP Consultants’ conclusion

In our view, the study is further evidence that chemical recycling still has many shortcomings. At the very least, however, this situation is becoming more obvious and visible thanks to increasingly well-founded analyses. This is also confirmed by the following chart from Ceflex.

Schwarz Group establishes complete recycling of HDPE packaging

The Schwarz Group’s 2024 sustainability report shows that it is consistently promoting a closed recycling loop for high-density polyethylene (HDPE) through its environmental division PreZero.

Thanks to state-of-the-art recycling technology, it has succeeded in establishing a complete cycle for used HDPE bottles. The starting point is private households, where the bottles are collected in yellow bags or yellow bins. The material is then sorted by type in highly specialized PreZero facilities for lightweight packaging. To increase transport efficiency, the HDPE packaging is pressed into bales and transported to the recycling plant in Grünstadt.

This is where the actual processing begins. The plants first sort the bottles by color before shredding them, washing them thoroughly, and then cleaning the resulting plastic flakes in a further step.

The result is a high-quality HDPE recyclate that is suitable for the production of new packaging. This material is used to make new HDPE bottles, which are already in use in Lidl and Kaufland stores – among other things as containers for cleaning agents and shampoos.

With this closed loop, PreZero demonstrates how technical innovation and consistent process design can turn used packaging into valuable raw materials that are returned to the production cycle.

For the packaging industry, this opens up not only ecological but also economic prospects by providing high-quality recyclates as a sustainable alternative to primary plastics.

BP Consultants’ conclusion

In our view, we need many more of these approaches through EPR systems that have direct access to recyclable materials. This will also enable relevant progress to be made with the polyolefin recyclates that are so urgently needed.

Strong alliance: Agilyx joins the Green Dot

Oslo-based Agilyx ASA is a specialist in chemical plastic recycling with operational roots in the US. In July 2025, it was announced that Agilyx would acquire a 44 percent stake in GreenDot, the group behind the German “Der Grüne Punkt” system – one of the leading players in European packaging recycling. The transaction values Der Grüne Punkt at around 200 million euros.

Der Grüne Punkt processes over one million tons of packaging waste annually, including more than 400,000 tons of plastics, and is currently establishing new sorting facilities in Germany, Austria, and Italy. For 2025, the company expects revenues of around EUR 400 million with double-digit EBITDA.

With this investment, Agilyx aims to strengthen its presence in Europe and, together with Der Grüne Punkt, build a global platform for supplying raw materials to the advanced recycling industry. Der Grüne Punkt will benefit from additional capital and Agilyx’s technological expertise to significantly expand its recycling capacities.

The partnership combines market-leading collection and sorting infrastructure with innovative recycling technology. It is an important step in achieving higher recycling rates and higher-quality recyclates – and thus a sustainable circular economy.

BP Consultants’ conclusion

In discussions, we often notice a lack of commitment on the part of the plastics industry to secure access to recyclable materials. As a provider of recycling technologies, Agilyx is now demonstrating that other stakeholders can also take this step.

German Packaging Award goes to dairy cups made from 30% polystyrene recyclate

The German Packaging Award 2025 announced its winners at the end of July. Over 200 entries from 15 countries competed in categories covering a range of materials. A total of 37 packaging developments emerged as winners. These included several plastic solutions that impressed particularly in the categories of sustainability and recyclability.

One example is the dairy cup with 30 percent polystyrene recyclate from Müller Service GmbH. The rigid plastic cup for dairy products was developed in collaboration with Ineos Styrolution and Aldi Süd and is already on the market.

The jury praised the packaging as an innovative use of recycled material in the food sector: it contributes to the high-quality recycling of polystyrene and prevents the material from ending up in downcycling. By reducing the use of virgin material and CO₂ emissions, the solution makes an important contribution to resource conservation and the circular economy.

The award shows that mechanically recycled polystyrene is not only technically feasible but also market-ready – a strong signal for greater recyclability in the food packaging sector.

INEOS Styrolution has already submitted a formal application to the European Food Safety Authority (EFSA) for its innovative recycling technology.

BP Consultants’ conclusion

In our view, this is a successful example that impressively demonstrates what can be achieved in the circular economy. In addition, polystyrene can relatively easily replace PP in many applications in the dairy products sector, as polypropylene has not yet convincingly proven its recyclability.